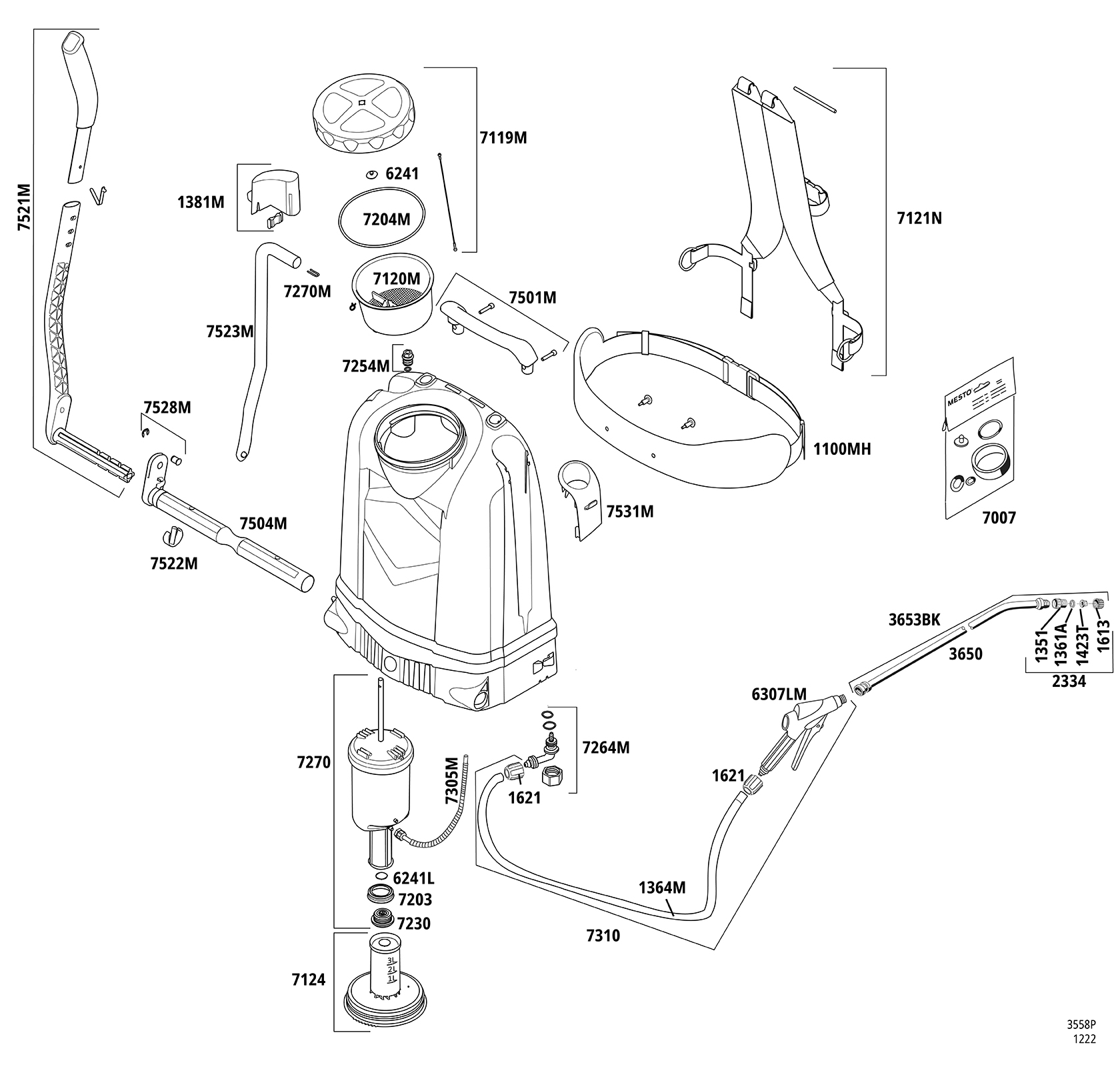

RS185 PLUS backpack sprayer

User-friendly backpack sprayer for professional use in the construction industry with internal piston pump for the highest level of user protection, offering the best wearing comfort due to padded S-shape straps as well as hip belt, pump lever that can be changed right/left, pump lever length and width adjustment, extra large filler opening, cover with loss protection and integrated measuring cups, ergonomic shut-off valve with integrated pressure gauge and filter, 50 cm brass spray wand with brass flat jet nozzle 80-04E, 18 l fill capacity, FPM seals, made in Germany, guaranteed 20-year availability of MESTO spare parts.

Ideal for: Construction industry for spraying viscous construction chemicals

| Product class | Performance **** |

|---|---|

| Spraying agents | Curing retarder, Construction chemicals, Primers, Impregnating agents, Oily agents |

| Nozzle code | 80-04E |

| EAN | 4000903001438 |

| Fill capacity | 18 l |

| Total contents | 20 l |

| Weight | 4,94 Kg |

| Article type | Backpack sprayer |

| Industry | Gardening and landscaping, Construction, Structural and civil engineering, Highway construction, Trade |

| Applications | Concrete curing, Concrete formworking, Priming, Impregnating, Lubricating, Pre-wetting |

| Max. operating pressure | 6 bar/88 psi/0.6 MPa |

| Tank material | Plastic transparent |

| Portability | Back, Carrying straps padded, Hip belt, Chest strap |

| Nozzle type | Spray nozzle, Flat jet rectangular distribution |

| Nozzle material | Brass |

| Spray angle | 80° |

| Spray wand material | Brass curved |

| Spray wand length | 50 cm |

| Shut-off valve material | Plastic |

| Shut-off valve connection | D10 |

| Hose diameter | D10 |

| Safety valve | no |

| Pressure gauge | Pressure gauge with indicator |

| Compressed air filler valve | no |

| Scope of delivery general | tank, Hose, shut-off valve, Spray wand, Nozzle(s), Instructions for use, Pump, Back padding or hip belt with back padding, Pump lever, Handle, Handle |

| additional equipment | Pump holder, Spray shield holder, filled spare parts kit, Filler screen |

| Device equipment | Safety interlock on the shut-off valve prevents unintentional spraying., Extra große Einfüllöffnung mit Sieb mit Einfülldeckel mit integriertem Messebecher und Verliersicherung. Dank Ablaufrinne fließt die ggf. verschüttete Flüssigkeit weg vom Rücken., Spray wand and extension wand holders for space-saving and safe storage., Spray shield holder for storing the spray shield on the sprayer., Professional back harness with chest strap and hip belt for back-friendly working., Embossed level scale to monitor the level at all times., Pump lever with length and width adjustment can be installed on the left and right., incl. filler screen for pre-filtering self-prepared biological mixtures., inkl. Spezialfett zur Pflege und Wartung der beweglichen Teile., Hose reinforced with fabric insert., Flat jet nozzle for area spraying., Large and ergonomically-shaped back support area for particularly comfortable carrying., ede51def-2f4b-48fa-b6c2-bb3852e24d11 |

Select the desired download.

| Type | Description | File extension | File size |

|---|

If you miss a download, please write us via our contact form.

The device must not be used for spraying pesticides.

Only trained, healthy and rested people may work with the device. You should not be under the influence of alcohol, drugs or medication.

Children and adolescents must not use the device. Keep the spraying devices safe from access to children.

Take precautions to prevent hazardous substances from being misused.

→ Accident risk!

Keep bystanders away during spraying.

Never spray on people, animals, electrical devices and lines, into the wind, or into bodies of water.

→ Risk of injury!

Wear appropriate protective clothing, goggles and respiratory protection in line with the applicable national regulations when working with hazardous substances.

Avoid ignition sources in the environment.

Do not allow the device to remain under pressure and/or exposed directly to sunlight. Make certain the device is not heated beyond the maximum operating temperature. (→Table 1).

Protect the device from frost and ammonia.

Never blow through the nozzles or valves with your mouth.

→ Risk of poisoning!

There is a risk of slipping or tripping on smooth or wet surfaces, snow, ice, on slopes and on uneven terrain.

Repairs and modifications to the device are not permitted. Have damaged parts or parts that do not work properly repaired immediately by our customer service department or by service partners authorized by us.

The effect of the safety valve must not be bypassed or made inoperative.

→ Explosion hazard!

Use only original spare and accessory parts. We cannot assume any liability resulting from the use of third-party parts.

When pumping, always observe the pressure gauge to ensure the maximum

spraying pressure is not exceeded (→ Table 1).

All excess pressure must be released from the device before filling, after use, before carrying out maintenance work, on work breaks, and before placing it in storage.

Points to note when transporting the device: Transport the device in such a way that it is protected against damage and tipping. All excess pressure must be released from the device.

→ Explosion hazard!

If the device leaks at the container, immediately depressurise the device and put it out of operation!

→ Risk of explosion!